A Coriolis flow instrument harnesses natural forces engaging mass flow influences to assess volumetric rates. As fluids progress through curled segments, torque effects provoke changes in liquid passage, directly corresponding to flow intensities, allowing exact throughput assessment. These devices exhibit broad flexibility, suitable for various flow materials with negligible head drop.

- Merits of Coriolis Flow Meters:

- Remarkable precision levels:

- Expansive parameter coverage:

- Dual parameter analysis:

Appreciating Coriolis Effect Applications

Coriolis flowmeters represent a specialized class of instruments optimized for quantifying substances within tubing. Exploiting Coriolis force mechanics, the instrument detects fluid displacement induced by rotation. Within rotating pipes, the fluid’s path shifts laterally, matched to stream direction. Instruments identify lateral shifts, transforming mechanical deflections into data associated with flow strength.

- Uses of Coriolis flowmeters include:

- Plant process management in natural resource sectors

- Pharmaceutical manufacturing

- Water resource management

Selecting Best Coriolis Instruments

Coriolis meters excel in providing high fidelity for fluid flow analysis. Yet, with varieties of available models, determining the best fit for applications may be demanding. Key considerations when choosing your Coriolis flow meter include: * **Characteristics of the fluid:** The fluid monitored impacts design and performance. * **Flow capacity range:** Meters operate within distinct flow limits. Confirm your needs are met. * **Accuracy standards:** Different use cases necessitate diverse precision levels. Outline these to pick models. * **Operational environment:** Factors such as temperature, pressure, and fluid viscosity change meter outcomes. * **System compatibility:** Assess integration and pairing with existing infrastructure.Advantages Offered by Contemporary Coriolis Instruments

Modern Coriolis devices provide a full array of perks for industrial needs. Fundamentally, these meters offer exceptional precision, facilitating precise flow tracking. In addition, Coriolis meters provide simultaneous density and volume quantification in one device, ensuring them highly suited for precise measurement. Furthermore, their durability enables operation in hostile environments.

- Accordingly, these devices see widespread use in markets like oil and gas, chemicals, food and beverage sectors, and pharmaceuticals.

State-of-the-Art Calibration Practices

Industrial environments requiring accuracy prioritize Coriolis flowmeter performance. Ensuring dependable, repeatable results demands refined calibration methods. These exceed basic protocols by integrating specialized instrumentation and detailed analysis.

Reference materials facilitate exact adjustments. By comparing meter outputs with known benchmarks, technicians detect variances and apply corrections.

- Multi-point calibration, assessing various flow rates, yields exhaustive performance profiling across meter ranges.

- Advanced software assists data management and visualization, enabling graph generation.

Consistent use of advanced calibration ensures optimal meter accuracy, driving process refinement across industries.

Handling Conventional Instrument Difficulties

Coriolis meters provide trusted accuracy and adaptability yet face occasional deficiencies. Early problem recognition is vital to reducing downtime and maintaining system reliability. Typical complications involve misalignment, often caused by improper setup, dirty sensing components, or flow disturbances. Reading inconsistencies may result from changing fluid properties, mechanical vibrations, or electromagnetic disturbances. Effective problem-solving requires thorough examination of conditions, sensor outputs, and operational logs.

- Ongoing evaluation for damage or contamination applies.

- Adjustment per guidelines maintains accuracy.

- Watching measurements aids early detection.

- Appropriate mounting helps reduce interference.

Using proven techniques fixes common Coriolis flowmeter challenges, ensuring reliable fluid monitoring and operational consistency.

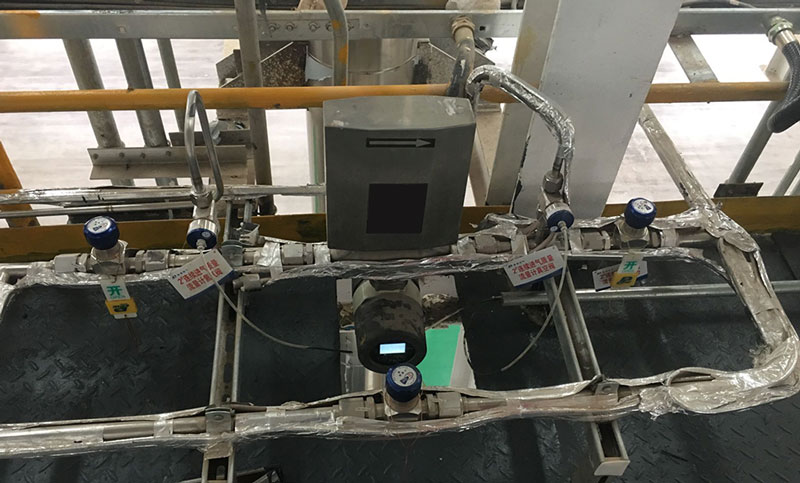

Industrial Automation with Coriolis Flow Meters

Devices supply exact volume determination within industrial applications. Utilizing the Coriolis effect triggered by fluid passage inside vibrating tubes, fluctuations in tube movement patterns correspond to fluid liquid quantity. This property enables state-of-the-art quantification of dynamic flows even in fluctuating environments.

They fit aptly a comprehensive mix of uses, including resource extraction. Their sturdiness makes them suitable for tough surroundings, and their integrated electronics enables smooth integration with production networks.

Accurate Fluid Flow Quantification via Coriolis Technology

Coriolis sensors deliver steadfast detection coriolis flujometro across extensive applications. They employ mass inertia principles to quantify mass flow, yielding excellent fidelity under complex flow regimes. Relative to alternative flow technologies, Coriolis sensors provide continuous readings, facilitating sensitive measurement. Their dual ability to measure mass flow and density makes them ideal for thorough flow assessments. Furthermore, Coriolis sensors exhibit reliability, thriving in challenging operating locations. This combination of precision qualifies Coriolis sensors as a top choice for demanding flow measurement situations.Coriolis Flowmeters in Energy Sector

Coriolis flowmeters have manifested themselves as robust tools in the oil and gas field. Their capacity to simultaneously measure flow volume and medium concentration renders them multi-functional for many operational tasks. In production workflows, Coriolis meters facilitate monitoring raw oil in transport tubing. They also fulfill vital roles in process regulation and guarantee accurate metering for billing.Coriolis Technology in Water Management

Flow sensors drawing on Coriolis principles give necessary metrics for fine-grained assessment in water management contexts. Utilizing momentum principles, they quantify path change through bent tubes. This sensitive data promotes real-time liquid volume tracking, key for boosting system operation.

- Deployments of Coriolis flowmeters in water systems extend to broad tasks, such as: distributing water to homes and industries, watching water usage for irrigation and power generation, and directing water flow in treatment plants.

- Positive Aspects for Coriolis flowmeters in this area provide: superior accuracy, broad scope across capacities, and easy maintenance requirements.

Improving Fluid Flow Metrics Through Coriolis Devices

Coriolis flowmeters have demonstrated themselves as solid solutions for gauging liquids. These systems apply the Coriolis effect to calculate both mass flow and fluid density. Implementing Coriolis technology can optimize measurement accuracy, diminish operating expenses, and yield insightful data about process parameters. Their multifunctionality enables use in a wide range of segments such as manufacturing.