custom-tailored cardboard packaging firm why choose creative shipping carton fabricators for superior protection?

Investigate the captivating universe of corrugated packaging creation by means of this detailed resource. The guide uncovers the crucial measures in changing plain sheets into robust containers that protect goods during transportation. Involving corrugation, branding, and packaging, we highlight the intricacies of this key arena.

- Explore the assorted kinds of corrugated packaging and their particular purposes.

- Explore the latest technologies used in corrugated box manufacturing.

- Examine the sustainability issues and renewable solutions.

If you are a scholar, practitioner, or market follower, this manual offers useful insights into the ever-evolving corrugated carton market.

Constructing Ideas with Corrugated Paperboard

Corrugated board, usually ignored as elementary packing substance, functions as a multipurpose crafting medium. Its solid essence backs the assembly of fresh constructions and styles, including practical containers to artistic ornaments. Using imagination, you have the power to modify this familiar fabric into everything remarkable.

List the endless possibilities of corrugated cardboard crafting by:

- Trying various methods such as slicing, bending, and stacking

- Applying recycled supplies for a green technique

- Exhibiting your crafts to energize others

With its affordability, accessibility, and versatility, corrugated cardboard is a perfect material for crafting enthusiasts of all ages and skill levels. Unleash your inner designer and let your creativity flourish with this humble resource.

The Harmony of Innovation and Artistry in Corrugated Packaging

Corrugated box production portrays a thrilling synthesis of technical knowledge and creative design. It rises above standard making; it emphasizes developing a protective case that defends products in transit while also making a memorable statement to buyers.

A capable fabricator realizes the nuanced elements of corrugated packaging board, modifying its measure, flute shape, and composition to match individual prerequisites of each item.

- Besides, decorative factors are indispensable.

- A skillfully constructed carton appears promptly noticeable on racks, winning the appeal of target audiences.

- Fundamentally, packaging design combines security and charm.

Managing Supply: Advancing Your Container Assembly

As enterprise prospers and demands climb, it's necessary to assure resources for meeting purchaser wants. Scaling your corrugated box production can be the key to keeping operations running smoothly and maintaining a strong reputation for reliability.

Primarily, analyze your production processes. Assess operational machines and workers to pinpoint probable limits or sections needing upgrading. Finally, study opportunities for enlarging manufacturing potential. Think about purchasing advanced equipment or modernizing existing tools to increase throughput.

Note that amplifying output is less important than refining entire operation. Employ agile production models to cut waste and maximize input use. Simplify processes, automate repetitive activities, and invest in staff training to cultivate a proficient team.

Concludingly, maintain firm alliances with contractors to preserve constant stock availability. Implementing these steps, you will productively advance packaging manufacturing and fulfill expanding buyer desires.

Enhancements in Packaging Technology

The packing area steadily improves, energized by desires for eco-conscious, cost-effective, and original strategies. Corrugated sheet, a constant substance for decades, witnesses revival energized by novel discoveries. From durable builds to intelligent functions, corrugated boards welcome modern innovations. Manufacturers are exploring new ways to enhance the performance of corrugated packaging, incorporating eco-friendly materials and processes. The product is a flow of fresh packaging designs remolding the trade setting.

These breakthroughs confront significant problems faced by firms, such as cutting waste and enhancing delivery networks. Consumers equally benefit from these innovations, with cartons that are safer and more functional. The horizon for corrugation is encouraging, packed with prospects for environmentally sound and efficient packaging frameworks.

Environmentally Friendly Corrugated Boxes: Green Alternatives

Corrugated cases play an important role in contemporary warehousing operations. Traditionally made from paper, these containers have a significant impact on the environment. However, increasing consciousness regarding eco-friendly methods applies equally to manufacturing carton goods. Thankfully, inventive approaches are accessible to improve green qualities of these cartons.

An important element involves employing reclaimed cardboard. Using factory or user remnants, the necessity for original supplies diminishes, safeguarding greenery and natural capitals.

Additionally, companies devote resources to green fabrication methods. This involves enhancing power usage and minimizing refuse across distribution networks. Consumers have a part by buying packages recognized as eco-conscious. Review logos such as FSC or SFI that validate responsible sourcing and fabrication.

Through applying these tactics, we preserve packaging as important business components while minimizing ecological disturbance.

Quality Control for Perfect Corrugated Boxes

Gaining high standards in carton production counts on precise evaluation techniques. Beginning with material acquisition and ending with product evaluation, all stages need constant vigilance. Severe controls manage fabrication stages to warrant every shipment matches highest measures.

- Examining base substances for flaws, durability, and consistency is vital to avoiding future issues.

- Conforming to strict dimensions and allowances during slicing and shaping guarantees containers are physically sound and suited for function.

- Repeated review of design application maintains colorful imagery and readable text

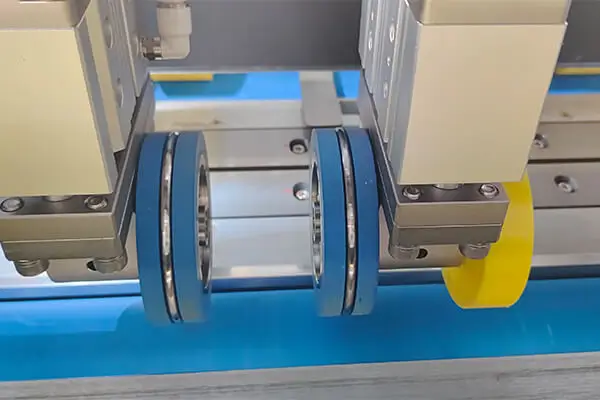

- Integrating robotic inspection technologies improves productivity and precision in quality checks

By stressing rigorous checks during manufacturing, producers offer packages that are sturdy and eye-catching. Such attention to detail appeases consumer desires and fortifies brand credibility.

Carton Printing: Identity and Influence

Packaging decoration printing forms a significant component of brand impression. When end-users spot your items, the packaging works as a critical device for making an impact. A precisely constructed visual on a carton can seize attention, illustrate brand spirit, and increase customer choices.

Also, container labeling supplies diverse selections to individualize your boxes. With bold hues to creative patterns, you may express brand character via the form of packaging.

Ultimately, corrugated box printing is more than just a functional necessity – it's a powerful means to strengthen your brand presence and connect with your audience.

From Basic Ingredients to Final Output: The Corrugated Box Procedure

The production of packaging is a captivating method that changes simple supplies into a crucial transport and protection tool. It originates by collecting pulp, commonly obtained from reclaimed resources. This pulp is then transformed into sheets of corrugated board, featuring a fluted center layer sandwiched between two flat linerboard layers.

These sheets are scrupulously formed following strict dimensions, then unified by professional machines to make the preferred box structure. Epoxies facilitate a major role in adhering parts securely, offering a solid and resilient structure.

Finally, products undergo stringent inspection processes to secure strength and adherence to market standards.

Starting from modest origins, the carton appears as a multifunctional packaging wonder, prepared to shield diverse goods throughout shipping.

Worldwide Container Sector: Changes and Prospects

The international carton market observes a stretch of advancement. This energetic domain is corrugated box maker stimulated by climbing purchaser demands for protection. Primary influences involve development of digital commerce and call for green packaging