Amidst the context of production systems, defending the unity and capability of passages is essential. Gathering of deposits within lines can significantly hinder fluid movement, reduce manufacturing caliber, and augments maintenance costs. To confront these issues, pipeline cleaning processes have materialized as notably successful fixes for flawless channel cleaning. A apparatus, generally a barrel-shaped apparatus, is moved through the conduit, adequately clearing accumulations and attaining optimal performance

Duct washing techniques deliver numerous advantages. They are malleable, ready to scrubbing pipes of mixed widths and substances. Furthermore, they are successful, finishing the work in a notably swift duration. By reducing downtime and improving pipeline functionality, pipeline cleaning systems support expenditure savings and amplified operational efficiency

Health-Driven Pipe Systems:

Maintaining pipeline hygiene is vital for confirming goods reliability and value of carried materials. Sanitary pigging systems provide a steady way to reach this purpose. Pigs, specific implements, are put in into pipelines to sanitize by getting rid of residues and impurities

- Several forms of sanitary pigs are accessible, each designed for special cleaning tasks.

- These pigs are developed from ingredients that fulfill stringent sterile standards.

- Scheduled sanitary pigging operations aid reducing product impurity, increase pipeline resilience, and enhance total functionality.

Leading-Edge Pigging Systems for Enhanced Functionality

pigging productsDuring the sector of pipeline management, advanced pigging methods have arisen as a critical tool for securing peak output and conservation. These cutting-edge systems apply clever schematics and facets to effectively purge, evaluate, and preserve channels from breakdown. From smart pigs loaded with instantaneous observation systems to tailored pigging apparatus developed for complex tasks, progression in this area is constantly breaking limits. By embracing these technologies, handlers can greatly improve pipeline soundness, reduce downtime, and increase operational output.

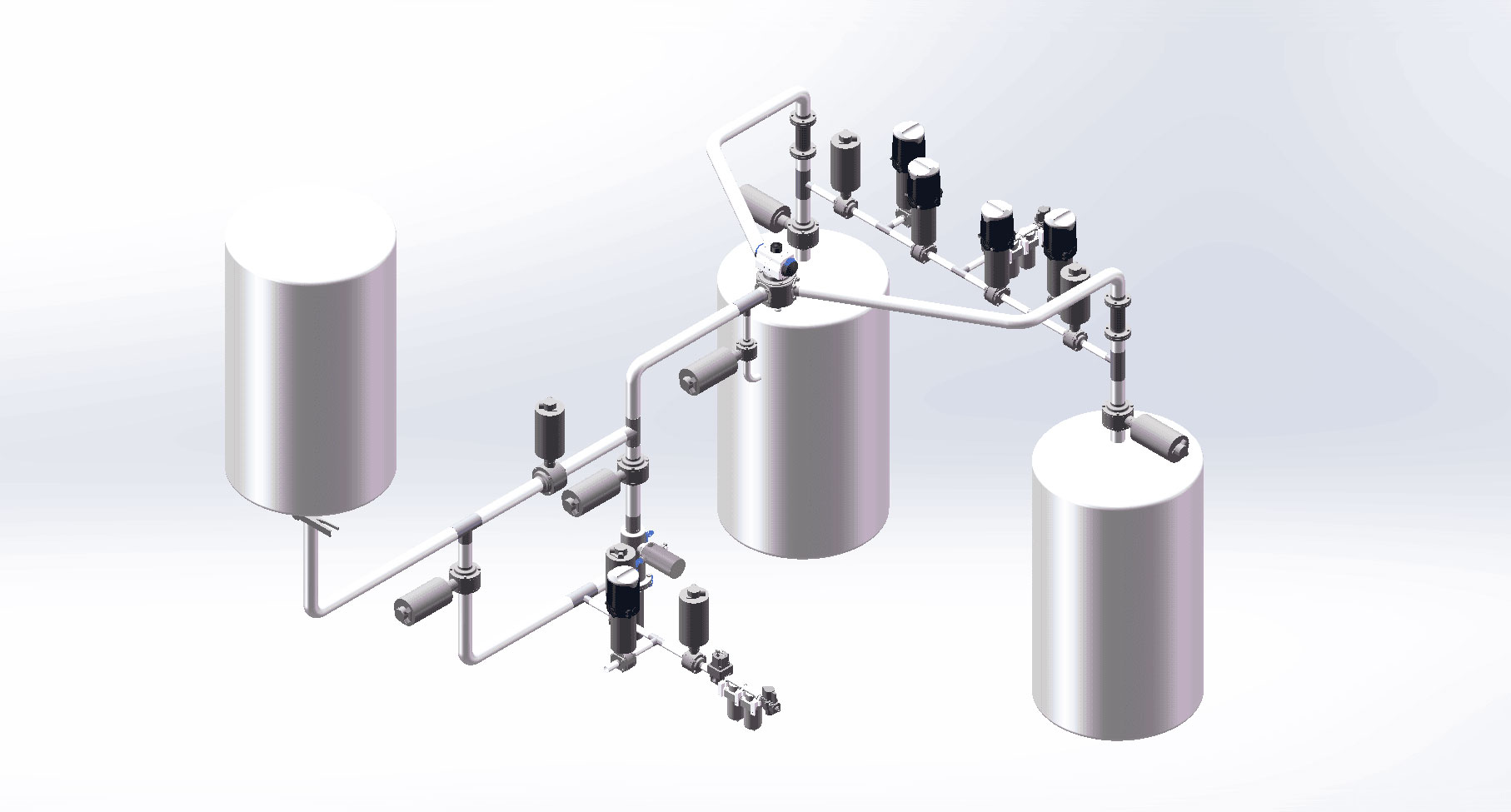

Inclusive Pigging Scheme Layout and Fitting

Such wide-ranging pigging system comprises a critical strategy for pipeline upkeep. This routine embraces the embedding of expert apparatus called pigs, which proceed through pipes to sanitize, inspect, and protect their firmness. The form stresses factors such as pipeline scale, composition, pig style, and operational requisites. A meticulously structured system provides effective pigging functions while decreasing downtime and potential breakdowns. Installation protocols mandate careful preparation, skilled experts, and strict adherence to safety directives to secure a secure and favorable conclusion

Mechanical Pigging Products for Comprehensive Functions

Mechanical pigging instruments are crucial assets applied across a wide collection of industries. These devices advance dependent and productive flushing, survey, and conservation of lines and other hollow fabrications. Pigging involves launching tailored tools known as pigs through pipes to undertake multiple assignments. Widely Known types of industrial pigging equipment include cleaning pigs, inspection pigs, and transfer pigs. Cleaning pigs are built to eliminate debris, build-up, and defilements from pipelines. Inspection pigs are armed with tools that retrieve information about the nature of pipe linings. Transport pigs are operated to carry materials through pipelines. The use of industrial pigging products grants numerous merits, such as diminished downtime, heightened pipeline strength, and bolstered operational functionality. These products are widely operated in branches such as oil and gas, water treatment, chemical production, and food manufacturing.Thorough Study of Pipeline Pigging

Pipeline pigging is an essential technique used within the oil and gas domain to survey pipelines. This important assignment involves introducing designed gadgets, dubbed pigs, into the pipeline. Pigs are built to pass through the coverage of the pipeline, conducting various purposes.

A types of pigs are obtainable, each made for a specialized mission. Common uses of pipeline pigging include evaluation for defects, decontamination, and pipe lining.

- Pros of Pipeline Pigging

- Results on Operational Efficiency

- Varieties of Pipeline Pigs

Established Sanitation utilizing Pigging Setups

Pigging solutions contribute a stable answer for achieving sanitation inside lines. These methods utilize dedicated instruments that proceed through the ductwork, productively removing contaminants. The practice is especially helpful for domains that insist on rigorous purity measures. Pigging approaches deliver a cost-efficient and timely approach for disinfecting ducts, mitigating the threat of pollution.

Opting for Pigging Equipment for Particular Requirements

Pigging apparatus serves a pivotal role in competent pipeline management. When selecting pigging equipment, it is important to consider the specific criteria of your application. This consists of reviewing elements such as pipeline girth, flow movement, product designation, and repair needs.

Numerous pigging types are offered, each developed for distinct reasons. For instance, some pigs are tailored for inspection, while others are deployed for wiping out residue or fractioning product loads.

What's more, pigging apparatus items should be harmonious with the transferred liquid.

It is often advantageous to seek advice from a authority in pigging equipment to make certain that you choose the most correct apparatus for your tailored criteria.

Systematic Pipeline Cleansing - A Benefit-Focused Approach

Cleaning frameworks present a broad spectrum of merits for areas dependent on pipes. By smoothly disinfecting and assessing line insides, pigging systems raise operational output and diminish maintenance fees.

A key benefit of pigging systems is their power to eliminate accumulation such as dirt, debris, and corrosion remnants. This routine maintenance helps maintain easy pipeline flux and obviates costly downtime.

In addition, pigging systems can be leveraged to check the integrity of pipelines, detecting latent faults before they worsen into grave concerns. This precautionary strategy promotes to enhance survival of pipelines and curtail overall maintenance costs.

Upholding Hygiene in Pigging Tasks

Swine breeding routines greatly hinge on appropriate hygiene regulations to restrain the propagation of microbes. Adopting rigorous hygiene requirements promotes a clean context for pigs, whereby generates advanced health outcomes and productivity.

Systematic cleaning and disinfection of sites is critical to eliminate the population of harmful bacteria. Adequate excrement management besides functions a crucial part in safeguarding hygiene.

Additionally, {workers