On occasions sophisticated profiled pipe design and fabrication, partnering with true experts is vital. These competent finned tube production adepts possess a detailed insight of heat conduction principles, matter traits, and the latest processes for creating top-quality heat exchangers. They conduct everything from first phase development and sample production to large-scale production and thorough review. Going for the right patterned pipe fabrication master can positively affect the efficiency and longevity of your device.

Cutting-edge Profiled Cylinders

Industrial manufacturing uses frequently demand highly efficient temperature dispersion, and top-tier finned lines are indispensable to achieving this. These fragments possess expertly designed flange geometries, commonly employing elaborate formulas to expand the surface available for heat dispersion. Building systems may involve rolling, linked by detailed fin formation and intermittently a unique surface processing to besides strengthen efficiency. Choosing the compatible finned section design is determined on the certain usage circumstances, notably fluid attributes, heat levels, and pressure degrees.

Made-to-order Augmented Copper-alloy Line Options

Meeting challenging thermodynamic management obligations? Our professional team constructs heat-sinked copper line packages precisely for your application. We apply advanced manufacturing techniques and exact calculations to boost heat distribution efficiency. Whether you're in the industrial sector, or need enhanced cooling of a delicate apparatus, our radiating copper channels can offer improved output. We evaluate factors such as fluid conveyance rates, environmental thermal states, and dimensional constraints to assemble a truly distinctive and impactful option.

Professionals in Aluminum Finned Tube Solutions

For years, we've been dedicated to providing unparalleled expertise in finned aluminum tube design, building, and placement. As leading professionals, we offer a comprehensive portfolio of services, catering to a comprehensive spectrum of industries, including temperature regulation, electricity generation, and industrial chemistry. Our unit of trained engineers maintains a intensive understanding of heat migration principles and component science, ensuring that every job we undertake delivers optimal efficiency and persistence. We are proud ourselves on delivering fitted strategies that precisely address our clients’ unique requests. Whether you require heat exchanger repair, refurbishment, or a comprehensive system blueprint, our focus to premium quality remains unwavering. Get in touch us today to consider your precise challenges.

Extended Tube Construction and Maintenance Presentations

Refining energy transfer efficiency is paramount in countless realms, and that's where specialized extended tube design and support packages truly shine. We furnish comprehensive services encompassing everything from initial concept to full-scale implementation. Our group of experienced technicians leverage advanced simulation techniques and area best systems to assemble individualized finned tube structures for a wide array of complex environments. Whether you're seeking to improve results, alleviate power costs, or tackle specific design obstacles, our improved tube expertise delivers excellent results. We also offer routine upkeep programs to ensure lasting effective integrity.

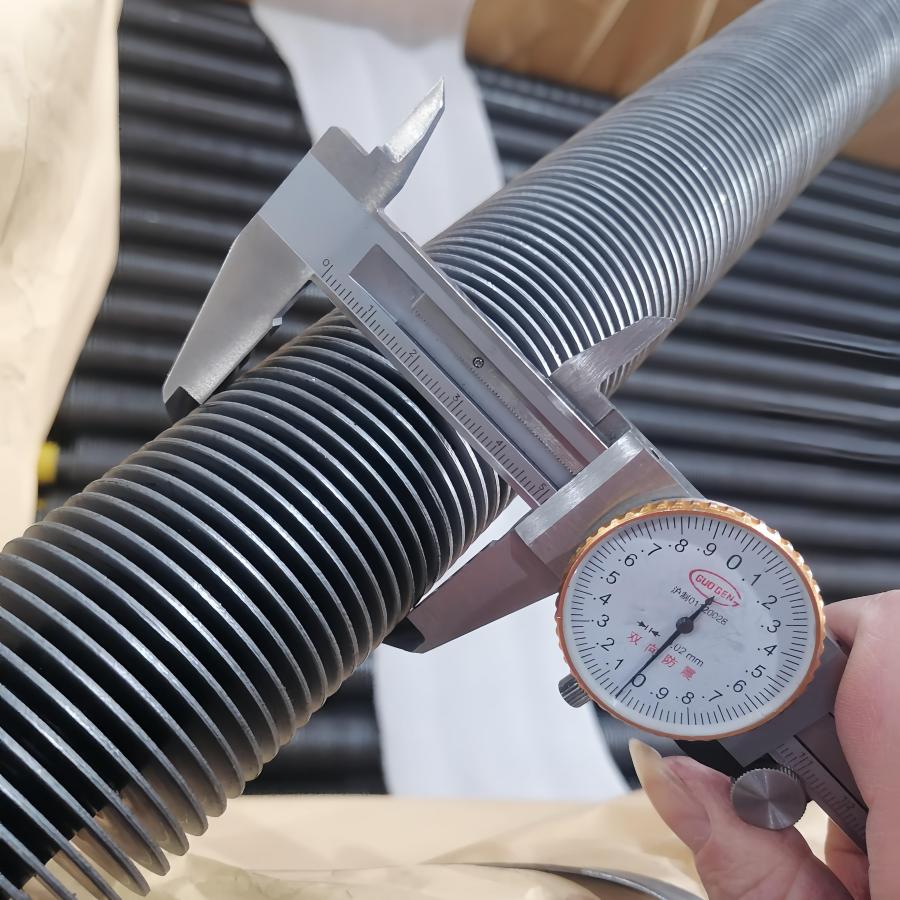

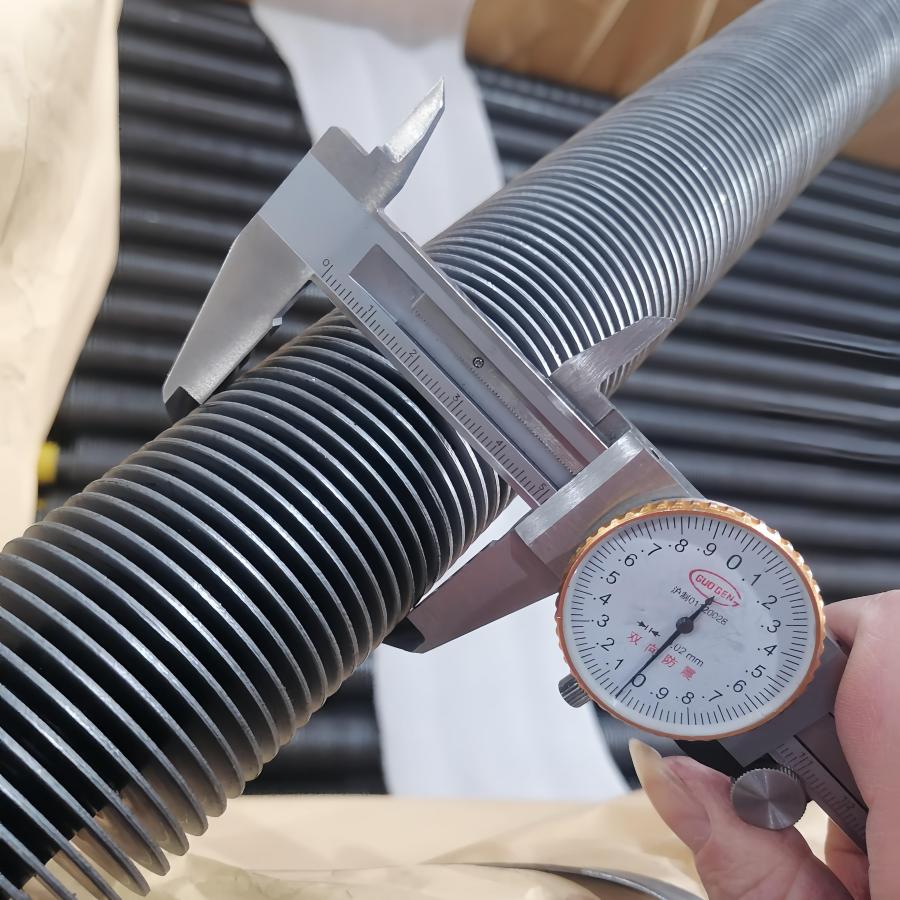

State-of-the-art Precision Augmented Tube Production

The needs of modern heat transfer systems are stimulating a change towards highly focused profiled tube fabrication. Traditionally, elementary fin configurations were acceptable, but now applications in digital equipment and process processing necessitate distinctly tight tolerances and complicated geometries. This involves precise bending of fins directly onto the tube body, often utilizing sophisticated cryogenic fabrication equipment to achieve the desired ridge scale, interval, and configuration. Furthermore, the composition selection plays a fundamental role, with specialty alloys frequently employed to elevate thermal operation while maintaining mechanical soundness. Class assurance practices are also indispensable to ensure stable grooved tube caliber.

Grooved Copper Pipe for Heat Exchangers

Innovative fin tubes heat dispersion systems frequently employ finned copper tubing as a crucial aspect in heat exchangers. The presence of fins, commonly made from light metal, significantly augments the surface zone available for heat removal, leading to a superior efficient heat transfer. These ribbed copper pipelines are often found in applications ranging from process processes, such as coolant management machinery, to domestic HVAC systems. The exceptional thermal thermal flow of copper, joined with the extended surface coverage provided by the fins, culminates in a significantly effective method for controlling heat. Different fin styles, including unbent and curly, present varying degrees of performance augmentation depending on the exact application’s requirements.

Innovative fin tubes heat dispersion systems frequently employ finned copper tubing as a crucial aspect in heat exchangers. The presence of fins, commonly made from light metal, significantly augments the surface zone available for heat removal, leading to a superior efficient heat transfer. These ribbed copper pipelines are often found in applications ranging from process processes, such as coolant management machinery, to domestic HVAC systems. The exceptional thermal thermal flow of copper, joined with the extended surface coverage provided by the fins, culminates in a significantly effective method for controlling heat. Different fin styles, including unbent and curly, present varying degrees of performance augmentation depending on the exact application’s requirements.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum augmented tubes offer a compelling combination of streamlined construction and remarkable performance, making them ideal for a varied range of factory heat transfer uses. Their unique configuration—featuring aluminum ribs attached to the tube exterior—significantly amplifies the heat exchange efficiency without adding substantial mass. This translates to decreased energy outlays and improved overall function reliability. Consequently, these tubes are frequently adopted in HVAC applications, refrigeration, and other heat convection processes where minimizing mass and maximizing thermal transfer are paramount concerns.

Finned Tube Fabric Options: Brass & Lightweight

While selecting finned tube fabric, engineers frequently review copper and aluminum. Copper offers exceptional oxidation resistance and superior caloric conduction, making it suitable for applications where superior heat movement is paramount, such as in cooling units systems. However, copper's greater price and conceivable for galvanic corrosion with other compounds can be limiting drawbacks. Conversely, aluminum provides a significantly lower rate and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Perfecting Heat Exchange with Finned Hollow Bodies

The operation of heat appliances frequently hinges on the design and application of finned sections. These structures significantly boost the surface area available for heat transfer, allowing for a much greater withdrawal of heat compared to simple, unfinned pipes. The advancement process involves a complex interplay of factors, including fin outline – such as fin extent, spacing, and breadth – as well as the component of both the fins and the root channels themselves. Careful consideration of the medium flow characteristics, whether it's air or a liquid, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven dissemination of the working material. Ultimately, a well-designed finned tube array delivers a important improvement in overall thermal capability within a given space.

Durable Finned Tube Networks for Factory Applications

Fulfilling the requirements of demanding engineering environments necessitates long-lasting heat conduction apparatus. Our finned tube offerings are engineered for exceptional performance, providing reliable heat dispersion in a range of applications, from fuel processing to environmental control. Constructed from top-quality materials and featuring advanced material immunity techniques, these assemblies minimize upkeep downtime and maximize operational productivity. The tailored fin design promotes greater heat transfer, even under harsh operating states.