Opening such examination concerning exact surface enhancement systems targeting fabrication territories

Gaining trustworthy outcomes across its fabrication actions? Fineness polishing remedies perform as important aimed at achieving high-quality section merit as well as elevated efficiency. We grant the inclusive collection including modern methods, covering electrochemical finishing, honing, including cutting, qualified to resolve even the most required uses. The proficient skilled team journies with customers to construct customized refinement outlines meant to increase surface traits and sustain precise wholeness. Summarily, these exact techniques contribute to reduced charges and amplified productivity for your company.

Fundamental Joint Sanitation Procedures & Equipment

Suitable seam cleaning is undeniably paramount for safeguarding the integrity of any constructed seam. A process removes residue, holes, and other adulterants that can compromise durability. Numerous procedures exist, including unmechanized scraping with cleaning tools, and mechanical polishing. Targeted hardware, such as lightweight power abrasive wheels, fine scrapers, and build-up methods, are frequently exploited for more robust results, particularly on large welds. Moreover, solvent agents can be administered to further eradicate stubborn residue. Selecting the suitable technique and relevant devices depends on the fabrication alloy, dimension, and necessary quality.

Linked Areas:

- Joining Assessment

- Joining Process

- Fabrication Security

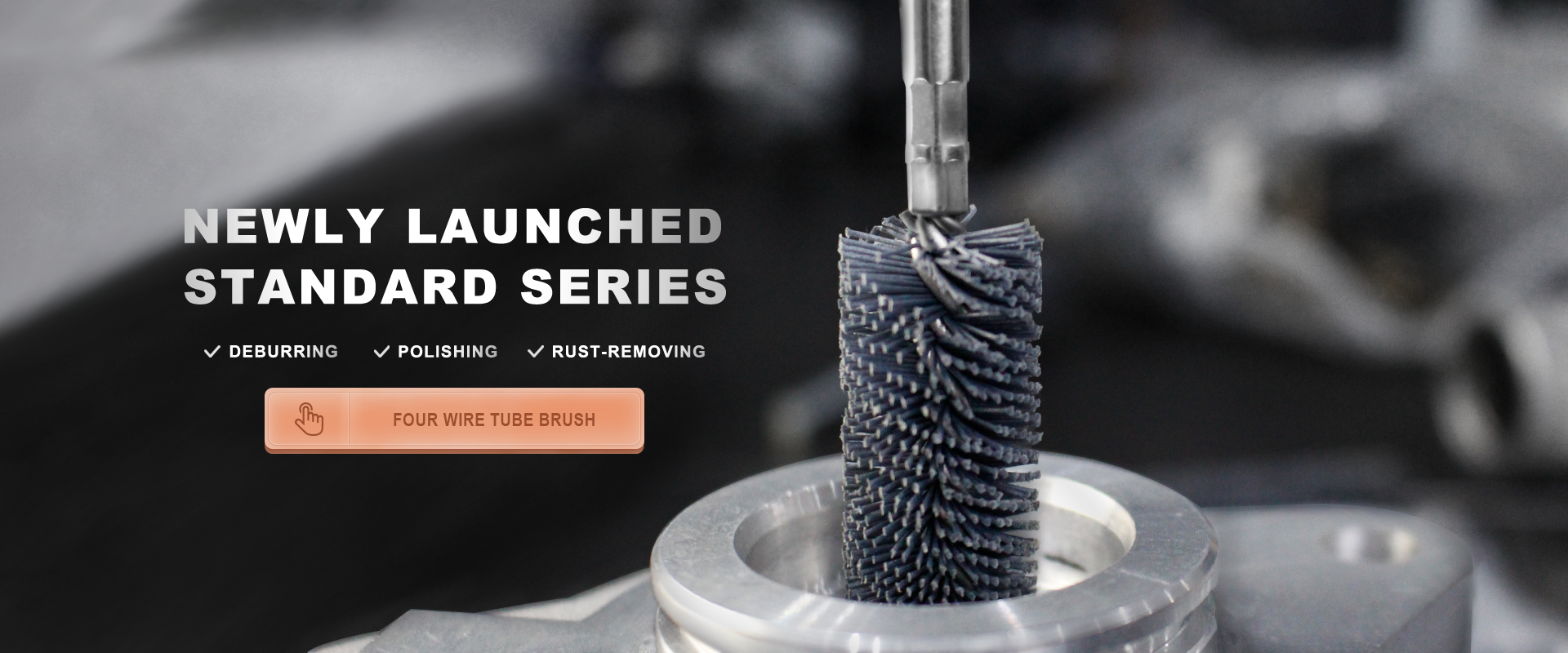

Foundry Deburring: Functions & Applications

Succeeding in a smooth, functional covering on created parts is crucial, and burr extraction plays a vital duty in that process. Conventionally, this was a manual, manual-work-heavy task, but modern metal fabrication operations increasingly leverage advanced edge-breaking technologies. These strategies range from simple machinery-aided brushing and grinding to sophisticated automated systems employing intelligent deburring modules and even abrasive blasting techniques. Ultrasonic edge cleaning offers a safe solution for delicate bits, while thermal deburring is frequently used for complex materials. The selection of the appropriate edge finishing operation depends significantly on the substance, part geometry, and desired look. As well, understanding the source of burr formation—often related to mold design or fabrication parameters—can help mitigate them altogether.

Electrochemical Strip Brush Applications

Powered finishing strip brushing systems find multiple utility across a span of industries, largely due to their gentle yet effective action. Specifically, they excel in removing intricate burrs from stamped metal sections, preparing faces for subsequent coating processes like powder spreading. Beyond deburring, these brushes are frequently used for accurate surface conditioning prior to welding, offering a superior alternative to abrasive procedures that can introduce surface irregularities. Furthermore, their ability to rigorously remove scale and oxides makes them valuable in preservation operations on industrial equipment.

Visible Refinement for Vital Components

Completing ideal performance and strengthened longevity for necessary machine components frequently necessitates tailored surface refinement techniques. This isn't merely about aesthetics; it’s about altering the minute structure of the substance to reduce drag enhance erosion resistance, and improve aggregate functionality. Diverse approaches, including shining, plating, and focused energy texturing, can be carefully applied depending on the distinct application and the planned outcome. The selection of a specified refinement method must always consider the medium's properties and the functioning environment to inhibit unintended consequences and maximize the component's consistency.

Intelligent Fusion Preparation Processes

The call for consistently high-quality welds in modern generation environments has spurred significant advancements in fusion post-processing techniques. Machine-based cleansing equipment are rapidly gaining popularity as a choice to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced units often incorporate technologies such as laser removal, high-pressure waterjet scouring, or specialized abrasive substance, ensuring efficient and precise slag clearing without damaging the underlying connection. Implementing these automated solutions leads to reduced personnel costs, improved safety, and a more consistent surface that directly impacts the constructional capability of the final component. The ability to integrate these tools into existing creation lines further enhances their appeal across a wide range of industries, including heavy machinery and shipbuilding.

Smoothing Components for Best Effectiveness

In order to ensure ideal effects from your materials, devising is a critical process. Residuals, a regular byproduct of the shaping system, can affect effectiveness, create operational hazards, and poorly damage visible texture. Therefore, comprehensive smoothing – which may involve artisan systems or digital mechanisms – is obligatory for giving a top-tier processed output adapted for its planned task. This action just upgrades functionality but also curtails the probable for damage.

Accurate Purification with Wipe Brush Practices

Performing remarkable neatness in challenging processing environments often requires specialized solutions. Ribbon buffing processes offer a effective tool to discard pollutants from complicated parts. These fresh practices utilize tailored strips to provide consistent interface – crucial for meticulous sanitation and ensuring element standard. Explore the benefits of stripe buffing systems for your next cleaning assignment.

Ionized Cleaning for Welds & Surfaces

Electrolytic washing offers a efficient method for preparing welds and various substrate kinds. This process, fundamentally implementing electrochemistry, cleanses oxides, scale, leftover welding fumes, and other debris that can affect ensuing processes like painting, evaluation, or further fabrication. Unlike abrasive techniques, electrolytic washing provides a non-aggressive action, minimizing erosion to the base product and leaving a remarkably sterile surface. It's especially advantageous for complex patterns and obscure areas where manual scrubbing would be impossible. A carefully controlled electrolyte liquid and electrical potential are indispensable for achieving consistent results.

High-tech Fabrication Deburring Approaches

Above traditional physical deburring, modern casting facilities are increasingly employing leading processes to achieve consistent edge finishing. These improved deburring techniques often involve a combination of automated platforms and precisely controlled standards. Abrasive deburring, for instance, offers exceptional accuracy and allows for fine geometries to be flawlessly cleaned, minimizing material removal and maximizing segment integrity. Furthermore, intelligent deburring cells, utilizing indexing tools, are becoming prevalent, providing increased throughput and dependable results, particularly for significant production runs. The selection of the appropriate finishing method depends heavily on the shaping composition, element geometry, and desired standard characteristics.

Sophisticated Detailed Smoothing and Strip Cleaning Approach

The relentless pursuit of surface integrity in modern manufacturing demands ever more tailored systems. Among these, precision finishing utilizing linear scrubbing process stands out as a efficient solution. This approach, frequently employed across diverse industries like automotive, offers distinct advantages in achieving even material elimination, glossing, and scraping results. Unlike traditional styles, strip bristle technology allows for highly controlled material elimination and the ability to access difficult geometries with a capacity of accuracy previously unattainable. Furthermore, advancements in hair adoption and drive construction continue to expand the applications of this vital buffing strategy.

machine tool industrial brush

machine tool industrial brush